Group

Group

AGENCIES

SPIKES

SPIKES

We make admirable quality of fabricated Spikes for various OEM manufacturers globally. The spikes we manufacture consists of highly sophisticated technology using imported wires and the speciality lies in producing these spikes precisely in various sizes. We manufacture 90 types of spikes; hence significant techniques are followed to maintain these spikes of equal Radius point. The procedure srinivasaures that its tip doesn’t break or bend while manufacturing. The Spikes are of best quality which increases your productivity, in the meantime it requires less costs for maintenance. |

||||||

|

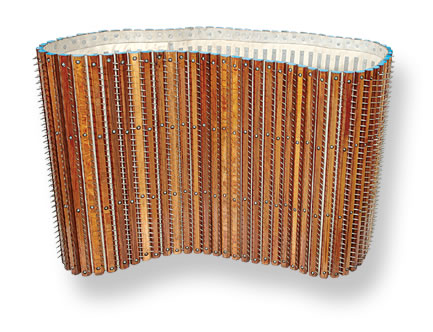

SPIKED LATTICE  We manufacture Spiked Lattice using cutting edge method which suits your blow room

machines like LMW, RIETER, TRUMAC, CROSROL and other OEM machineries. Our firm also

supplies Spike Lattices to reputed textile mills and other international machine

manufacturers. In general, 4 types of raw material are used specifically by us to

produce this Spike Lattices. Our Spikes are manufactured particularly from Lamination

wood which gives a long life and increases your productivity, speed and quality.

Moreover, we purchase the raw materials exclusively from ISO companies to maintain

our best quality. Our purchased raw materials include

We manufacture Spiked Lattice using cutting edge method which suits your blow room

machines like LMW, RIETER, TRUMAC, CROSROL and other OEM machineries. Our firm also

supplies Spike Lattices to reputed textile mills and other international machine

manufacturers. In general, 4 types of raw material are used specifically by us to

produce this Spike Lattices. Our Spikes are manufactured particularly from Lamination

wood which gives a long life and increases your productivity, speed and quality.

Moreover, we purchase the raw materials exclusively from ISO companies to maintain

our best quality. Our purchased raw materials include

|

||||||

|

PLAIN LATTICE  We manufacture Plain Lattice that suits the machineries like LMW, RIETER, TRUMAC,

CROSROL and other OEM machineries. Lamination Wood / Seasoned Wood are used to produce

these types of Lattices. Products manufactured through season wood prevent the plain

lattices from Cracks / shrinkages; We use only endless belt to manufacture the lattice,

due to this purpose the joint will never get broken. we assure that it does not

affect your production timings or quality. The Raw Materials to produce these Lattices

are purchased from ISO companies which includes

We manufacture Plain Lattice that suits the machineries like LMW, RIETER, TRUMAC,

CROSROL and other OEM machineries. Lamination Wood / Seasoned Wood are used to produce

these types of Lattices. Products manufactured through season wood prevent the plain

lattices from Cracks / shrinkages; We use only endless belt to manufacture the lattice,

due to this purpose the joint will never get broken. we assure that it does not

affect your production timings or quality. The Raw Materials to produce these Lattices

are purchased from ISO companies which includes

|

||||||

|

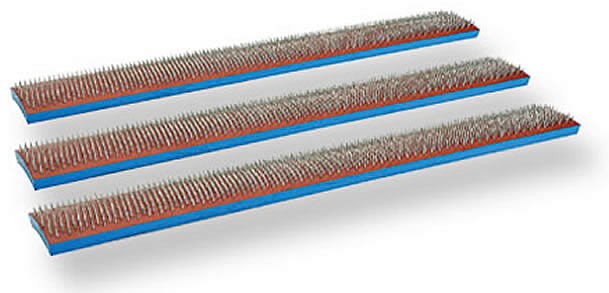

KIRSCHNER BEATER LAG  Srinivasa manufactures KIRSCHNER Beater Lag that suits your machineries like LMW,

RIETER, TRUMAC, CROSROL and other OEM machineries. Laminated wood is the object

used to produce Krishner Beater Lag. We use Spike as a raw material for this product.

Usability of Steel Spike and automatic machine for fitting purpose makes Krishner

Beater Lag look equivalent without height variation. As we give prior importance

to quality, your fiber opens well and increases your productivity and quality. Moreover

we use apt technology to ensure Spikes Gap which prevents the tip from breaking

or bending.

Srinivasa manufactures KIRSCHNER Beater Lag that suits your machineries like LMW,

RIETER, TRUMAC, CROSROL and other OEM machineries. Laminated wood is the object

used to produce Krishner Beater Lag. We use Spike as a raw material for this product.

Usability of Steel Spike and automatic machine for fitting purpose makes Krishner

Beater Lag look equivalent without height variation. As we give prior importance

to quality, your fiber opens well and increases your productivity and quality. Moreover

we use apt technology to ensure Spikes Gap which prevents the tip from breaking

or bending.

|

||||||

|

ALUMINIUM LAG  Aluminium Lag (Hard Waste Opener) that suits your machineries such as LAROCHE, PLATTS

are made precisely using imported European machines. An automatic machine fits this

pin in Aluminium lag, hence its Quality is enriched and Time delay is avoided. Using

advanced technology and Aluminium Bar we produce Lags in large quantities. Our quality

adherence increases your production and great care is taken to fulfill your requirement

Aluminium Lag (Hard Waste Opener) that suits your machineries such as LAROCHE, PLATTS

are made precisely using imported European machines. An automatic machine fits this

pin in Aluminium lag, hence its Quality is enriched and Time delay is avoided. Using

advanced technology and Aluminium Bar we produce Lags in large quantities. Our quality

adherence increases your production and great care is taken to fulfill your requirement

|

||||||

|

CONVEYOR BELT  We have taken dealership of Conveyor Belt from an ISO Company and this belt suits

your machineries like LMW, RIETER, TRUMAC, CROSROL and other OEM machineries. Varieties

of Belts are purchased in big coil and are provided to customers in required size

(Heater joint – (Endless Type) along with guarantee. Massive Stocks of Conveyor

Belts on multiple sizes are supplied to customers as a customer benefit.

We have taken dealership of Conveyor Belt from an ISO Company and this belt suits

your machineries like LMW, RIETER, TRUMAC, CROSROL and other OEM machineries. Varieties

of Belts are purchased in big coil and are provided to customers in required size

(Heater joint – (Endless Type) along with guarantee. Massive Stocks of Conveyor

Belts on multiple sizes are supplied to customers as a customer benefit.

|

||||||

|

SPINNING WOODEN ROLL  We use seasoning wood to manufacture Spinning Wooden Roll that suits your machines

like LMW, K.T.T.L, ZINSER, MARZOLI and other OEM machineries. We also supply this

Spinning Wooden Roll to outstanding reputed mills and other international machine

manufacturers. Equivalent sizes of rods are used for weight consistency and usage

of this Spinning Wooden Roll prevents the product from weight variation & shrinkage.

Fresh qualities of woolen clothes are used to get best quality of yarns. Bulks of

raw materials are available for immediate huge orders and instant deliveries are

made on customer requests.

We use seasoning wood to manufacture Spinning Wooden Roll that suits your machines

like LMW, K.T.T.L, ZINSER, MARZOLI and other OEM machineries. We also supply this

Spinning Wooden Roll to outstanding reputed mills and other international machine

manufacturers. Equivalent sizes of rods are used for weight consistency and usage

of this Spinning Wooden Roll prevents the product from weight variation & shrinkage.

Fresh qualities of woolen clothes are used to get best quality of yarns. Bulks of

raw materials are available for immediate huge orders and instant deliveries are

made on customer requests.

|

||||||

|

COMBER BRUSH  We manufacture Comber Brush so as to fit all your comber machines like L.M.W, RIETER,

MARZOLI and other OEM machineries. We also supply Comber Brush to reputed mills

and other international industries. Imported fibres and seasoned woods are used

to make this brush, reasoning to this shrinkage and cracks are highly avoided. Usability

of Automatic machine gives work efficiency to the product and this can be easily

maintained by your industrial technicians.

We manufacture Comber Brush so as to fit all your comber machines like L.M.W, RIETER,

MARZOLI and other OEM machineries. We also supply Comber Brush to reputed mills

and other international industries. Imported fibres and seasoned woods are used

to make this brush, reasoning to this shrinkage and cracks are highly avoided. Usability

of Automatic machine gives work efficiency to the product and this can be easily

maintained by your industrial technicians.

|

||||||

|

CARDING PHILIPSON BRUSH ROLLER  We do Carding Philipson Brush Roller that suits your all carding machines like L.M.W,

RIETER, TRUMAC and other OEM machineries. Seasoned woods are used to make this roller

and due to this cracks and shrinkages is greatly avoided. The brush is manufactured

by Mexican fibre for work efficiency and usability of automatic machine keeps the

quality alike. We also use quality polish rods to give a long life to brush rollers.

We do Carding Philipson Brush Roller that suits your all carding machines like L.M.W,

RIETER, TRUMAC and other OEM machineries. Seasoned woods are used to make this roller

and due to this cracks and shrinkages is greatly avoided. The brush is manufactured

by Mexican fibre for work efficiency and usability of automatic machine keeps the

quality alike. We also use quality polish rods to give a long life to brush rollers.

|

||||||

|

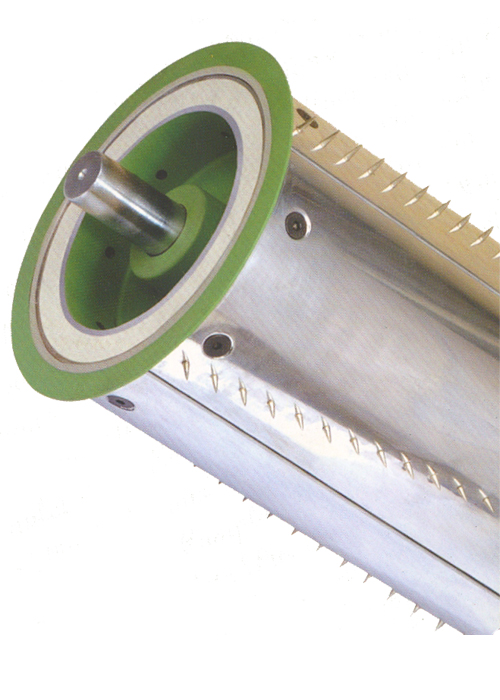

PULLEY SPIKED (PINNED) ROLLER AND ERN PIN BEATER  We make pin beater that suits all your Blow room machineries like L.M.W, RIETER,

TRUMAC and other OEM machineries. We make High quality specifically to manufacture

this aluminium bar and Cylinder. The materials Cylinder and Aluminium Bar are additionally

imported from European countries. As a result good cotton opening is achieved. The

manufactured pins are fixed using automatic machine; hence their heights are equivalent

and prevent the pins from falling. The fitted pin doesn’t either bend or break,

so its productions and durability are magnificent.

We make pin beater that suits all your Blow room machineries like L.M.W, RIETER,

TRUMAC and other OEM machineries. We make High quality specifically to manufacture

this aluminium bar and Cylinder. The materials Cylinder and Aluminium Bar are additionally

imported from European countries. As a result good cotton opening is achieved. The

manufactured pins are fixed using automatic machine; hence their heights are equivalent

and prevent the pins from falling. The fitted pin doesn’t either bend or break,

so its productions and durability are magnificent.

|

||||||

|

TRUMAC CARD - FBK & DSK BEATER  We manufacture this Pin Beater using Aluminium Extrusion Material. With the help

of the Automatic Machine, we drill the spike and fit the drilled spike in this beater

through automation. During operation, the Hardening Steel Spike neither tends to

bend nor the point breaks. Owing to these features, we are able to obtain excellent

cotton opening with enhanced quality. We adhere to a strict inspection and testing

procedure of manufactured products at all stages so as to deliver the best quality.

We manufacture this Pin Beater using Aluminium Extrusion Material. With the help

of the Automatic Machine, we drill the spike and fit the drilled spike in this beater

through automation. During operation, the Hardening Steel Spike neither tends to

bend nor the point breaks. Owing to these features, we are able to obtain excellent

cotton opening with enhanced quality. We adhere to a strict inspection and testing

procedure of manufactured products at all stages so as to deliver the best quality.

|

||||||

|

CARDING | LYCRIN PIN BEATER  This Pin Beater is manufactured using cutting-edge technology with the help of Aluminium

Extrusion Cylinder and Automatic Hardening Spike is made use of in this Beater.

This spike is not subjected to any wear & tear during its operation in the cylinder.

This use of Pin Beater provides improved quality and productivity. Besides, the

presence of sufficient space/gap between two pins in this Beater prevents the overlapping

of cotton, offering you exceptional cotton opening with superior quality.

This Pin Beater is manufactured using cutting-edge technology with the help of Aluminium

Extrusion Cylinder and Automatic Hardening Spike is made use of in this Beater.

This spike is not subjected to any wear & tear during its operation in the cylinder.

This use of Pin Beater provides improved quality and productivity. Besides, the

presence of sufficient space/gap between two pins in this Beater prevents the overlapping

of cotton, offering you exceptional cotton opening with superior quality.

|

||||||